hard anodizing aluminum diy

Next we seal the anodize simply by rinsing it with water or other chemicals depending upon your needs. The anodizing voltage is also increased to 50-90 volts depending on the type of aluminum being used this is a very hard and highly wear-resistant coating.

The temperature often rises during the anodising process.

. Distilled water is best if you have some. Let the acid cool between anodizing runs or rig up a cooler. This is not true Type-III but is in fact just a thick Type-II coating Type-II5.

You should probably turn on the ceiling fan or open the garage door. Step by Step home DIY anodizing of aluminium Mix up 10 to 20 Sulphuric Acid solution with pure distilled water. 4 grams of NaOH in 196 ml of tap water.

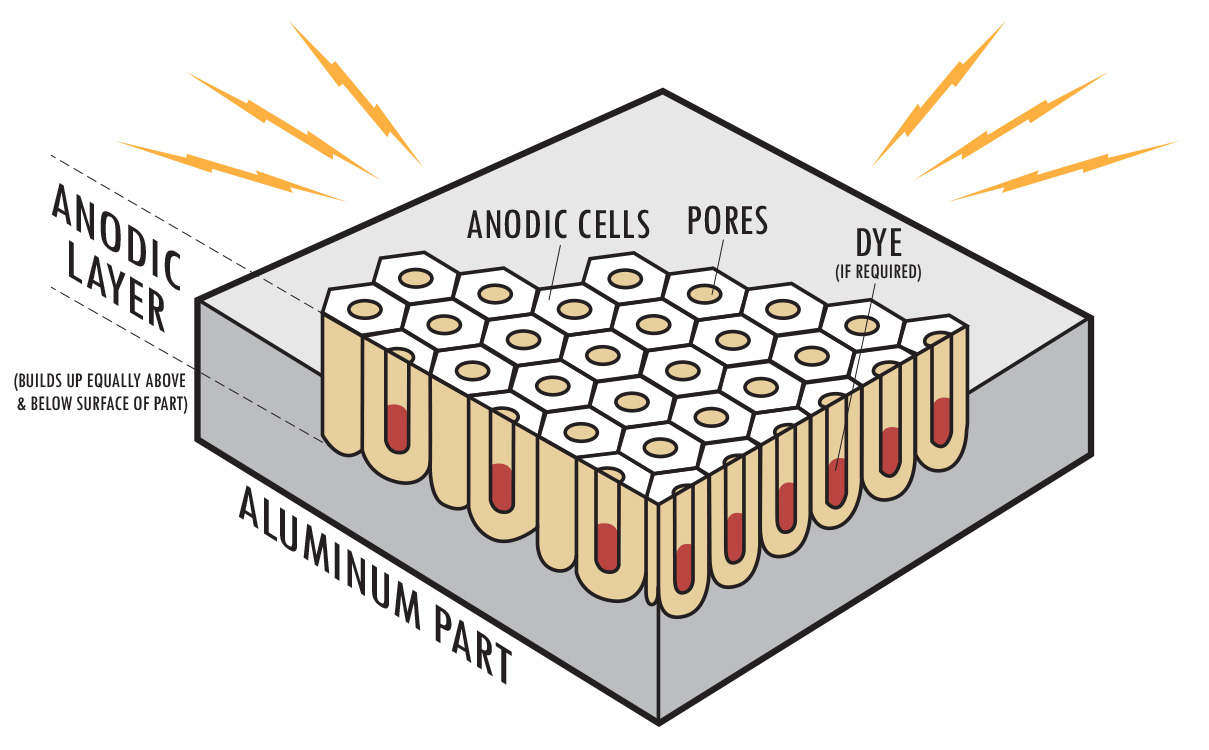

This protective oxide layer has a rougher surface that allows dyes or paints to stick to the metal. Remember only lead or aluminium in the tank. It is harder than aluminum so it offers a measure of protection.

Fill a plastic bucket with a 11 mixture of battery acid and distilled water making sure to add the acid to the water not the other way around. Also you need to do that in a well ventilated area due to poisonous gas output. Remove parts from acid bath and rinse with distilled water.

I think that with some practice that it wouldnt be difficult to get goo. You should not allow the acid to become warm - ideally it wants to stay at 20C. The negative lead is connected to the cathode which can be made of stainless steel.

This will be used to clean and prepare the aluminum surface. Remove from the dye solution and rinse with boiling water then set the dye by placing the. The hard anodizing process has the characteristic that it is harder than the film processed by the usual method and has better abrasion resistance.

This is called hard coat or hard anodizing. Observe the white bubbles around the material if its affects only one side rotate the element on each 30 seconds. Heat to boiling and allow the metal to boil in the solution for about 30 minutes.

How do you hard anodize aluminum at home. Keep temp at 70-72 degrees F. Make a 2 dilute solution of sodium hydroxide Drain Cleaner NaOH if you desire an etched surface prior to anodizing.

The temperature often rises during the anodising process. Dye parts if desired in warm dye 100 - 140 degrees F. It also gives the aluminum corrosion resistance.

Seal parts by placing in boiling distilled water for 20-30 minutes. Add color to your anodized metal by placing the metal into the dye solution. For anodizing a two-electrode setup is used where the anodizable aluminum piece is the anode.

Or ¾ cup water to 1 teaspoon NaOH. If you are not sure its working use an ammeter to see whats going on. The cathode will fizz a lot the anode will also show some small bubbles.

Mix with plastic or wood tongue depressor. Hard anodising is performed with a weaker solution of sulfuric acid and a lower temperature acid bath. Type-III thickness is defined as any thickness greater than 1mil 254 microns.

A power source with connections Acid Distilled water A cathode A container Dye only needed if you want to make it a different color Aluminum or titanium wire A degreaser An acid neutralizer An agitator optional Safety gear A. Normally for Type II anodising we have our acid bath around 15-20 degrees. Anodizing parts in my garageI am an amazon affiliate and make profits from the links belowRed dyehttpsamznto2JoKYnhBlue dyehttpsamznto2Hvtsw5Hot.

The end result is a pattern of open holes in the surface of the aluminum which is also the reason anodize makes the material harder. For type III hard anodizing the temperature must be only 2-4C. Hard coat anodizing is a surface finishing that an anodic aluminum oxide film is treated with a low-temperature electrolytic cell or a special electrolytic cell with various organic acids.

Most places that improperly say that their product is Hard Coat or Mil-Spec anodized only anodize only anodize to a thickness of 26 - 30 microns 101 - 12 mils. For type III hard anodizing the temperature must be only 2-4C. First time trying to anodize aluminum parts at home and for a very reasonable price.

Fizz the aluminium in caustic soda solution until it looks a nice grey colour. The acid will heat up. Prepare your aluminium piece.

Normally for Type II anodising we have our acid bath around 15-20 degrees. Cover your working area in something disposable. Hard anodising is performed with a weaker solution of sulfuric acid and a lower temperature acid bath.

Typically a depth 10 microns results in a coating that is very hard and scratch-resistant. The aluminum object is connected to the positive lead usually red. It is possible to achieve a 002 thickness with a 50 Penetration and 50 Buildup on the surface.

Anodizing aluminum creates a thin layer of aluminum oxide on the metal. Both electrodes need to be seperated and parallel to each other. This is what you need to anodize aluminum.

Diy Aluminum Anodizing In 10 Steps Sendcutsend

How To Anodize Aluminum The Federal Group Usa

Diy Manual Mechanic Anodize The Aluminum Diy Coloring

Aluminum Anodizing 3 Minute Tutorial Youtube

How To Anodize Aluminum At Home Make It From Metal

Everything You Need To Know About Anodizing Aluminum 3erp

Homemade Anodizing Automatic Artisan

Anodising Aluminium At Home Results

Shopbuilt How To Anodize Aluminum Youtube

How To Anodize Aluminum Parts Easily In The Home Shop Msfn Youtube

Anodizing Aluminium At Home First Experiments

Homemade Anodizing Automatic Artisan

Diy Aluminium Anodising How To Improve Your Anodising

Anodising Aluminium At Home Results

Category Anodizing Aluminum Observations

Diy Anodize Aluminum At Home With A Battery Charger Youtube

Diy How To Anodize Aluminum At Home Youtube

How To Anodize Aluminum My Approach On Diy Small Scale Anodizing By Deeworks Youtube

Mini Slingshot How To Anodize Aluminum Diy Giaco Giaco Youtube